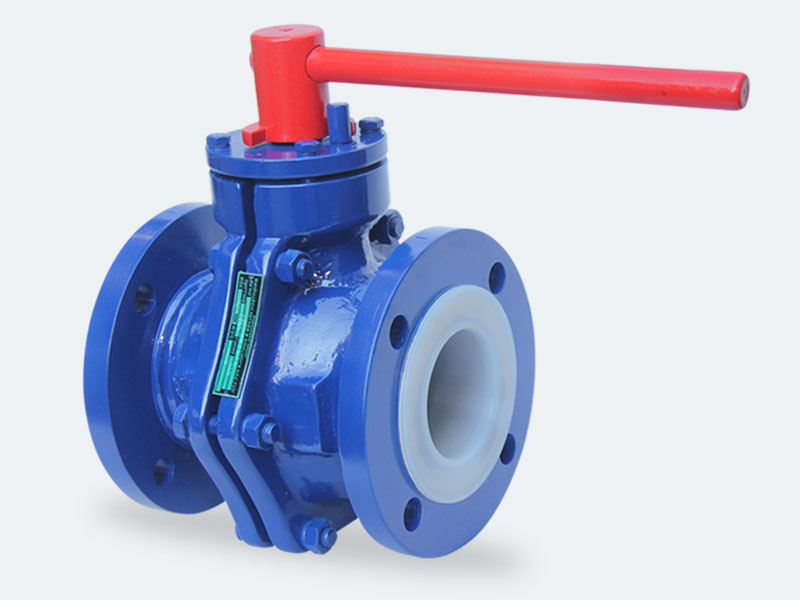

Briflon® lined Ball Valves are generally made from Cast Ductile Iron with lining. It is a full port, Two PC Design, Bolted Body Construction with Integral floating Ball Stem Unit, Replaceable Seat, Bubble Tight Shut off, Glandless Design, Maintenance Free, Full Flow Efficient, Low Torque manually lever operated for easy operation. Confirming to mfg. std. of BS 5153 and testing std. of BS 6755 part 1.

| SR.NO. | PART NAME | MATERIAL |

| 1 | BODY | ASTM A395 DUCTILE IRON + PFA/FEP LINING |

| 2 | INTEGRAL BALL WITH LINING | WCB/CF8/CF8M + PFA/FEP LINING |

| 3 | TOP COVER | ASTM A 216 GR WCB |

| 4 | STOPPER PIN | ASTM A 216 GR WCB |

| 5 | LEVER | M.S |

| 6 | LEVER BOSS | ASTM A 216 GR WCB |

| 7 | SEAT RING | PTFE |

| 8 | CHEVRON SEALING SET | PTFE |

| 9 | DIAPHRAGM | PTFE |

| 10 | DIAPHRAGM BACK UP | SS 304 |

| 11 | WASHER | M.S |

| 12 | DISC SPRING | SPRING STEEL |

| 13 | AL. CAP SCREWED | C.S |

| 14 | HEX. HEAD SCREWED | C.S |

| 15 | STUD & NUT | ASTM A 193 GR B7 & ASTM A194 GR 21-1 |

The lining is securely locked into the deep machined groove slot into the body & holes in casting ball under melting processible of FEP or PFA. This prevents liner to collapse or blow out under full vacuum/high pressure/temperature applications.

Encapsulated one PC design ball & stem. No possibility of rupture of ball & stem joint. Ensure trouble free frequent operations.

Two PC Design Bolted Body Construction with Stainless Steel Fasteners, minimize the joint leakages.

The contact area (sealing area) of ball with seat is very less, thus operating torque is much lower than the plug valve. Lever is compactly designed to operate the valve with very low torque. The valve above 4” size are offered with worm gear box actuation for smooth operation.

The “Briflon®” fully lined ball valve are designed in accordancewith flange dimension of ANSI B16.5, & face to face dimension of ANSI B16.10 permits these valves to replace with any standard ball valves without altering existing piping.

Minimize the Pressure drop and increase the flow capacities

| SIZE (NB) | A |

| 15 | 127 |

| 20 | 127 |

| 25 | 127 |

| 40 | 165 |

| 50 | 178 |

| 80 | 203 |

| 100 | 229 |

| 150 | 267 |

| BODY (HYDRO) | 20 Kg/cm2g (Before Lining) |

| SEAT (HYDRO) | 10 Kg/cm2g (Before Lining) |

| SEAT (PNEUMATIC) | 07 Kg/cm2g |

| Size | 25 | 40 | 50 | 80 | 100 | 150 |

| Torque (NM) | 13 | 14 | 25 | 45 | 80 | G.Box |

| Cv | 55 | 200 | 275 | 650 | 1300 | 2850 |

| TYPE | PFA/FEP |

| SPARK TEST | 15 K.V D.C |

| THICKNESS | 3.0 MM OVER ALL WETTED PARTS |